Protech Food Machinery AB, based in Lönsboda, Sweden, is a leading manufacturer of equipment for the thermal treatment of food products, including smoking, cooking, drying, and cooling. Their product range encompasses machines for various processes in the food industry, such as spiral smoking, batch smokehouses, continuous smoking, cooking, cooling, cleaning, and smoke generators.

All development and manufacturing are conducted in their own factory, ensuring direct contact with clients without intermediaries. Protech’s success is built on close cooperation with customers, creating unique solutions and remaining fully committed until production meets expectations.

Their equipment is designed to heat treat and smoke various types of meat, fish, poultry, and plant-based products, catering to the diverse needs of the food processing industry.

SPIRAL SMOKING-DRYING-COOKING

batch smoke chamber

cold smoking/fermentation

COOKING CHAMBER

INTENSIVE COOLING

CLEANNING

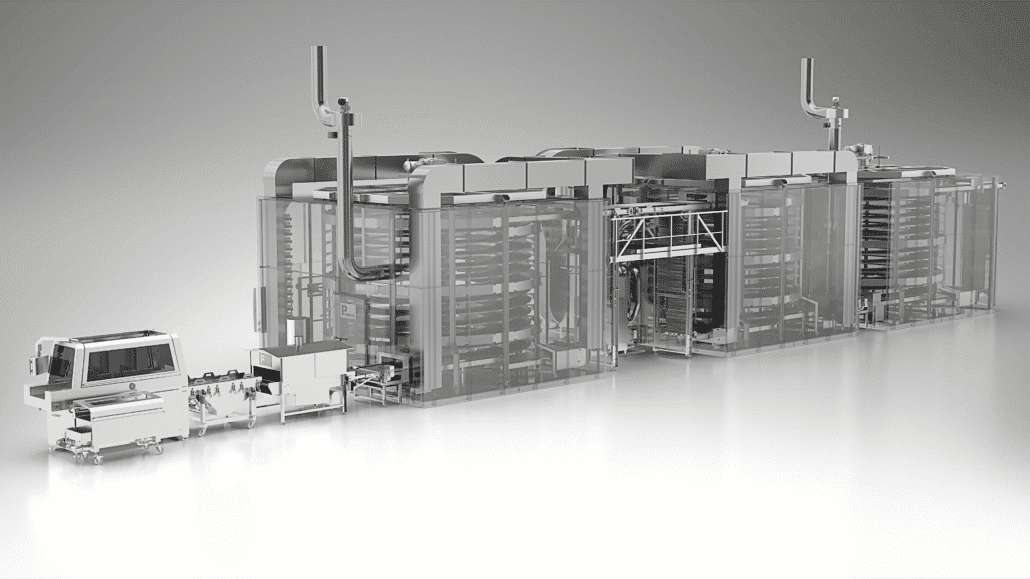

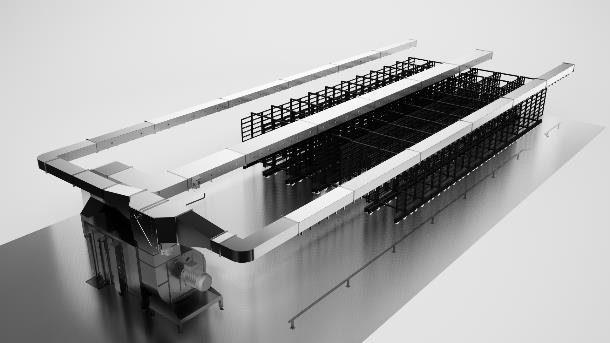

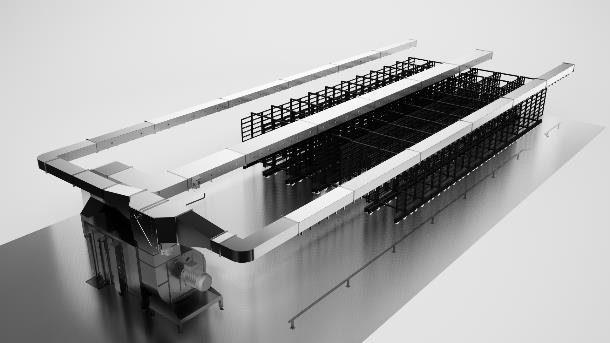

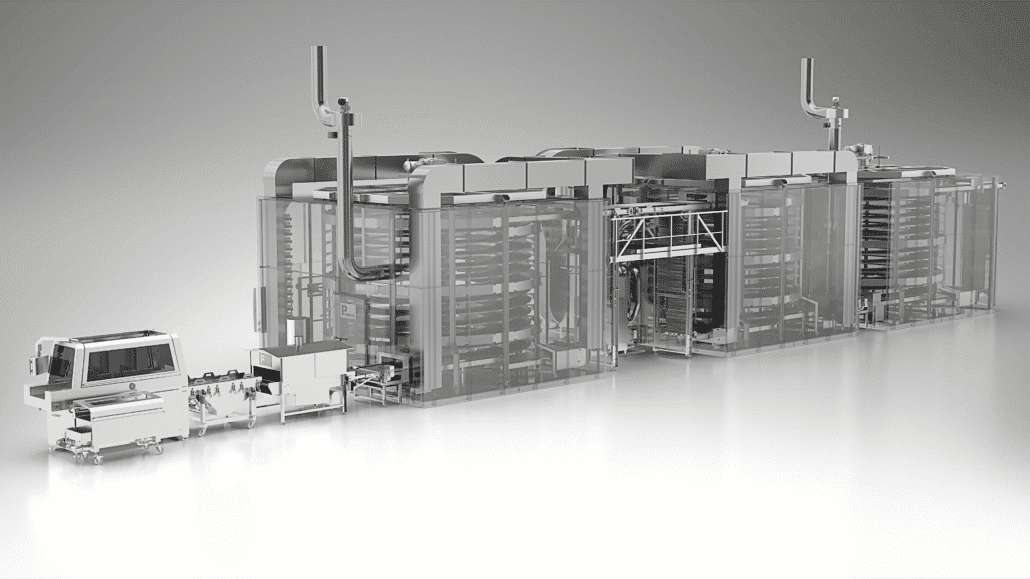

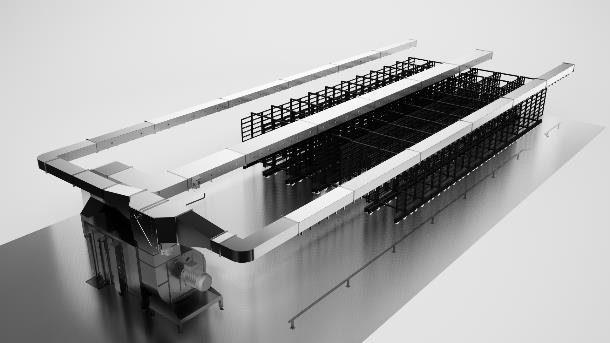

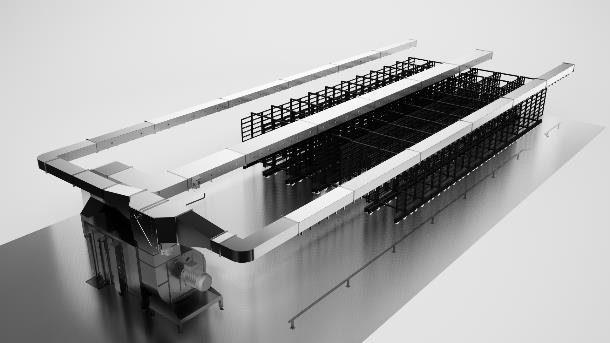

SPIRAL DRYING-SMOKING-COOKING

The equipment is built for in-line / continuous drying, smoking and cooking bacon and similar products. Smoking is with traditional smoking and liquid smoke.

PROTECH SPIRAL-DRYING-SMOKING-COOKING SYSTEM

The Protech Automated Spiral Smoking/Cooking System is the ultimate solution for meat processors that want to take their production capabilities to the highest level of product quality, yields and labor optimization. The Protech Spiral System provides a continuous process that significantly reduces labor and increases yields and production.

UNIFORM CONSISTENT PROCESS

The Protech Spiral System is an in-line system that requires all product to enter in the same position at the same temperature continuously. The temperature of the system is monitored and controlled during the cooking/smoking process. All product exits the system at the same position and consistent temperature.

PROTECH SPIRAL SYSTEM REQUIRES ONLY TWO OPERATORS TO PRODUCE 4000 Kg (8000 lbs) OF FINISHED BACON PER HOUR

The Protech Spiral System is fully integrated and does not require any additional accessories or equipment (such as smoke trollies, smoke sticks, etc.) Bacon operations that are manual can require up to 40-plus employees to operate, Protech Spiral System only require two.

batch smoke chamber

MEAT, FISH OR POULTRY

The smoke chamber is suited for drying, smoking and cooking processed meat products, fish and poultry within a temperature ranging between 15-90°C. The construction allows for processing of many different types of

products in a cost efficient way with optimal results. The unique air circulation guarantees a consistent result for all products.

PERFECT AIR CIRCULATION

The unique alternating flap system continuously changes the air circulation across all the products. This ensures a completely even and dry smoke process for all the products and ensures an even color and weight reduction throughout

the entire chamber. The forced air circulation is produced by a heavy duty centrifugal fan which is controlled by a frequency converter for exact air flow. This allows for a very exact and correct air speed for each individual

product.

FLEXIBILITY AND QUALITY

As we both build and construct the machinery we can adjust the equipment according to our customers needs. Both construction and design can be tailored to suit their products and production. Components of the highest quality and

use of the latest technology guarantees the equipment´s reliability and durability. All manufacturing and construction take place in a modern environment designed for food industry equipment.

cold smoking/fermentation

The Cold Smoking and Maturing Plant is designed for smoking and maturing of salami, raw ham and similar meat products with a temperature of 15 – 35°C.

DESCRIPTION

The plant consists of a central air conditioning unit and tubes for existing room. A fan ensures uniform drying and treatment of the products. Smoke is supplied by a smoke generator placed together with the conditioning unit.

CONTROL

The plant is equipped with computer controls. The computer holds a capacity of 99 programmes, wich can be easily, found by the operator. Temperature and relative humidity are controlled precisely throughout process.

VENTILATION

The forced air-circulation in the room is produced by a powerful centrifugal fan placed outside the room. The fan is operated by a frequency control.

HEATING AND COOLING

Heating and cooling coil is made of stainless steel and placed together with the fan.

COOKING CHAMBER

The cooking chamber has been constructed for cooking sausages, ham and similar products that requires a temperature of 70 to 90oC.

ALL STEEL CONSTRUCTION

The cooking chamber is constructed with 1.5mm stainless steel plates welded together for a totally air and water tight construction. This eliminates the need for rubber gaskets. The modules have 80mm isolation to minimize heat loss.

HEATING & VENTILATION

The forced air circulation is generated using powerful circulation fans. One fan over each trolley.

MICROPROCESSOR

The cooking chamber is fully computer controlled that monitors and controls the entire production. This ensures exact regulation of the parameters through the entire process.

INTENSIVE COOLING

Constructed to cool down the product after smoking and cooking before it’s transported to packing or refrigeration. The cooling process can be done using water and air or brine.

ALL STEEL CONSTRUCTION

The cooling chamber is constructed with 1.5mm stainless steel plates welded together for a totally air and water tight construction. This eliminates the need for rubber gaskets.

COOLING & VENTILATION

The stainless coil unit is placed alongside the chamber forcing the air to pass through the products.

MICROPROCESSOR

The cooling chamber is fully computer controlled that monitors and controls the entire production. This ensures a stable, efficient and economic run all week – all year – every year.

CLEANNING

Protech has developed machines, systems and a cleaning agent that are adapted for the “up to date” food industry and its production. Protech Foam.

Protech Foam is a strong alkaline foam cleaning agent especially developed for cleaning of smoke chambers and smoke trolleys. Its qualities are adapted for an efficient removal of tar and soot which can arise during the process by a modern smoke technique.

PROTECH CIP SYSTEM

Automatic washing system for smoke- and cooking chamber’s. The CIP system is controlled from the chambers microprocessor which makes it possible to wash unattended. The equipment consists of a central pump, buffer tank for water

and dosage pump for detergent. Nozzles placed in the whole chamber guarantee an efficient cleaning where no manual washing is needed.

PROTECH SMOKE STICKS WASHER

The smoke stick washer is designed to wash sticks, slaughter hooks and all other small metal tools used in the food processing. The washer has a compact drum construction giving an exceptional persistence of the machine and optimum

washing condition.

PROTECH TROLLEY WASHER

This automatic trolley washer allows you to wash trolleys and nets at the same time. It has a movable washing ramp with flushing nozzles that move back and forth. Carts are pasteurised with steam after washing. With our built-in

water recirculation system, it consumes minimal water. The wash has a built-in transport system that eliminates the need to move the trolleys manually in the cabinet. It has a capacity of up to 4 trolleys with nets in 15 minutes.