Backsaver is a Dutch company specializing in the production of high-quality stainless steel lifters and tippers for the food industry since 1990. Their machines are designed to be user-friendly, enhance productivity, and minimize the risk of workplace injuries.

Backsaver products are adaptable to various container types, including large plastic bins, nestable crates, totes, vats, and barrels, making them versatile solutions for diverse production processes. The company places great emphasis on hygiene and food safety, designing machines with components that ensure consistent product cleanliness and user safety.

Their equipment features an IP56 protection rating, allowing it to be cleaned using standard high-pressure washers. With over 75 years of experience and an in-house design and manufacturing facility in the Netherlands, Backsaver delivers customized solutions tailored to the unique needs of each production facility.

Backsaver ST

Standard Tipper

Backsaver NTLT Buggy Lifter/Tipper

Backsaver LT Lifter/Tipper

Backsaver CD 1400 Combo Bin Dumper

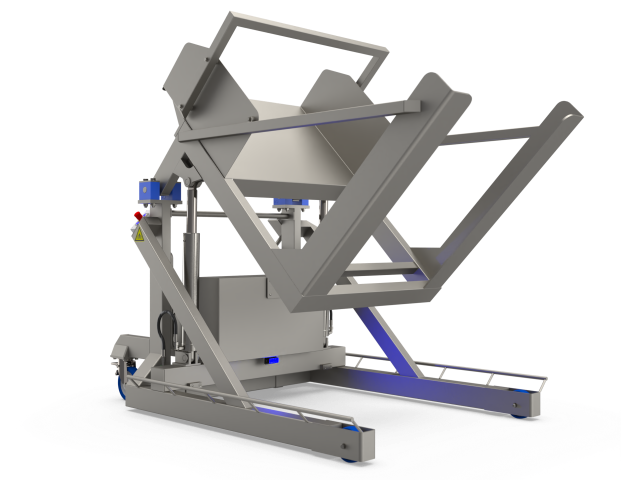

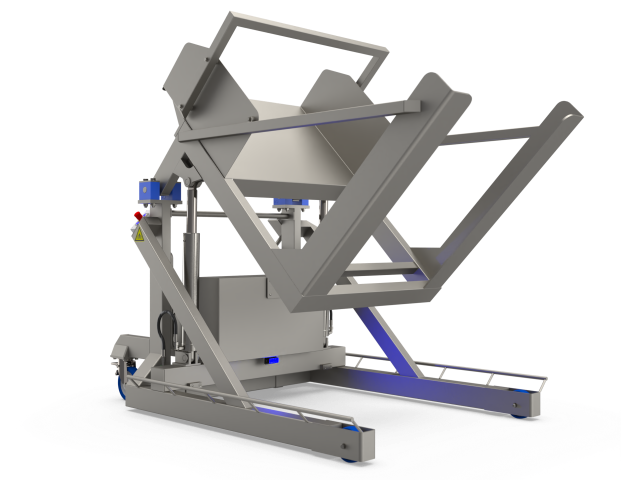

Backsaver ST

Standard Tipper

The Backsaver ST Standard is designed to tip large bins, tubs, or crates at work table height and can be customized for various containers. Ideal for deboning facilities, it boosts productivity and reduces workplace injuries by eliminating manual lifting and bending.

Powered by a rechargeable battery, it operates anywhere on the work floor and handles up to 50 tons per charge. Safety features include gravity-driven lowering, a backup alarm, and stable locking casters. The stainless-steel construction ensures easy cleaning and meets food industry standards.

Standard features include independent dual-side controls, a single hydraulic cylinder, and hold-to-run safety buttons. Optional upgrades include increased dumping height, customized chutes, and adjustable tipping angles. Built in the Netherlands since the 1990s, it’s durable and efficient.

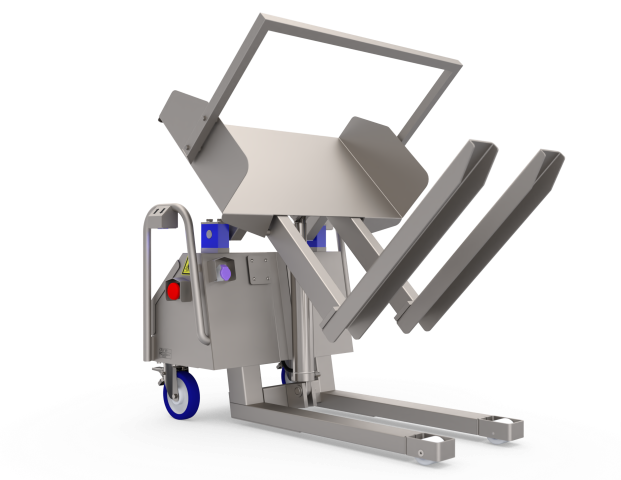

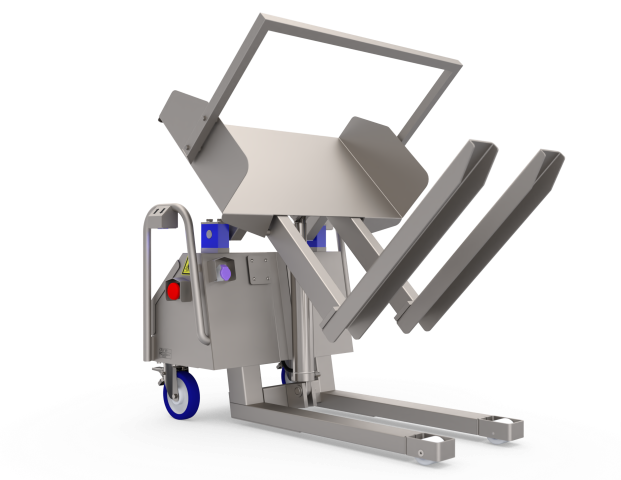

The Backsaver NTLT is a lifting and tipping machine designed for DIN9797 200- or 300-liter meat carts, ideal when the Backsaver NT’s dumping height isn’t sufficient. Its lift-and-tip system raises buggies to the desired height and smoothly tilts them, reducing manual lifting and lowering the risk of injuries, while boosting efficiency and throughput.

Equipped with a rechargeable battery, it operates flexibly across the work floor, even in refrigerated areas, handling up to 30 tons on a single charge. Independent dual-side controls make it easy to integrate into process lines or use with machinery such as conveyors, grinders, or packers.

Safety features include gravity-driven lowering, twin hydraulic cylinders, an audible alarm, and a flashing LED beacon. Constructed from stainless steel for optimal hygiene, it meets food industry standards and allows for easy cleaning with power washers. Designed and made in the Netherlands since 2011, the NTLT is durable, efficient, and safe.

Backsaver NTLT

Buggy Lifter/Tipper

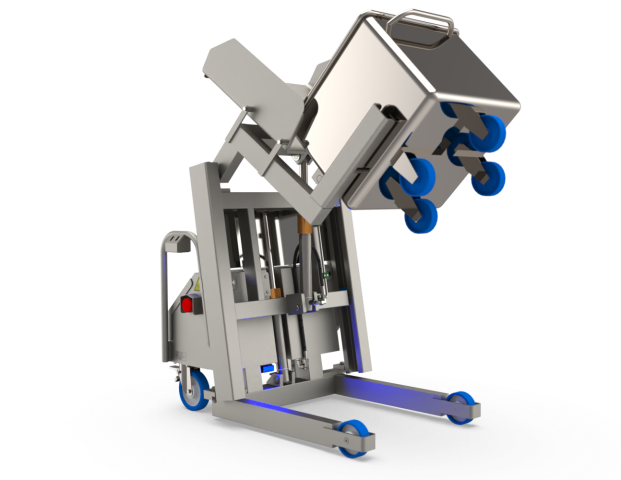

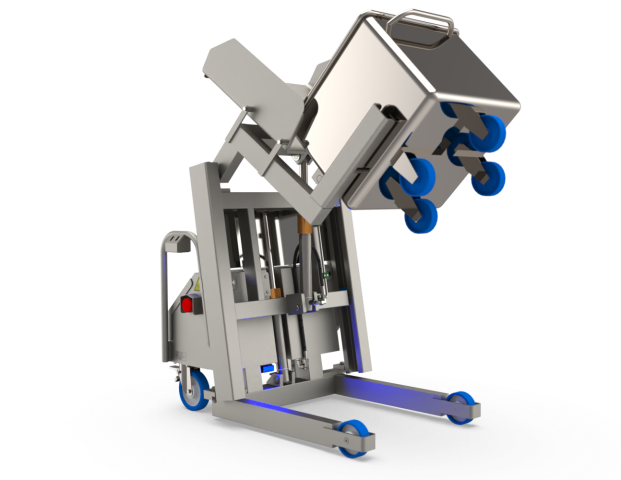

Backsaver LT

Lifter/Tipper

The Backsaver LT is a lifting and tipping machine designed to handle large bins when the Backsaver ST’s dumping height isn’t sufficient. Its lift-and-tip system raises heavy bins to the desired height and smoothly tilts them, making it ideal for busy areas or varied locations.

The machine enhances production efficiency while reducing workplace injuries by eliminating manual lifting and bending. Independent controls on both sides allow seamless integration into process lines or use with equipment such as grinders, separators, and packers.

Powered by a rechargeable battery, the LT operates anywhere on the floor, including refrigerated areas, and can handle up to 40 tons of products on a single charge. Safety features include gravity-driven lowering, a hydraulic cylinder, locking swivel casters, an audible alarm, and a flashing LED beacon to ensure stability and operational awareness.

Constructed from stainless steel, the LT meets stringent food industry hygiene standards and allows easy cleaning with power washers. Designed in the Netherlands since 2007, it offers a compact yet robust solution for demanding tasks.

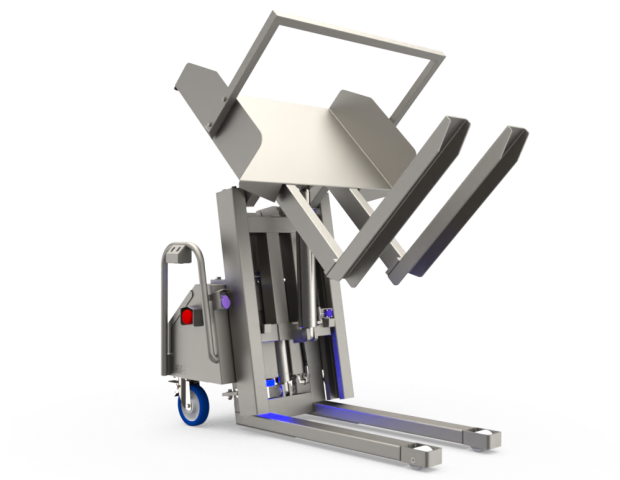

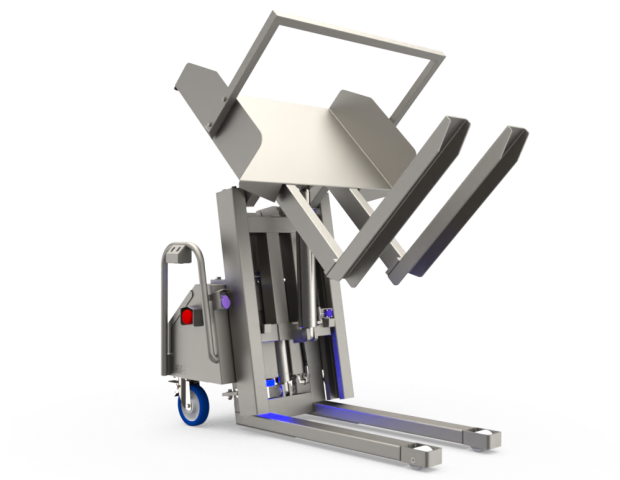

The Backsaver CD is a heavy-duty tipping machine designed to handle large containers such as plastic bins, pallet crates, and bulk boxes, with a capacity of up to 1,500 kg (3,500 lbs) and heights up to 1,400 mm (47.2″). It’s powered by a rechargeable battery and twin hydraulic cylinders, allowing smooth tipping motions and handling up to 60 tons on a full charge.

Ideal for fixed locations but occasionally relocatable, the CD improves workplace safety and efficiency by eliminating manual lifting and bending, reducing injury risks. Independent controls on both sides ensure ease of use and integration into process lines for product transfers, such as filling screw conveyor hoppers.

Safety features include gravity-driven lowering, an audible alarm, and a flashing LED beacon for added caution. Constructed from stainless steel, the machine meets food industry hygiene standards, allowing thorough cleanups with power washers. Designed and manufactured in the Netherlands since 2015, the Backsaver CD is durable, efficient, and perfect for demanding tasks.

Backsaver CD 1400

Combo Bin Dumper