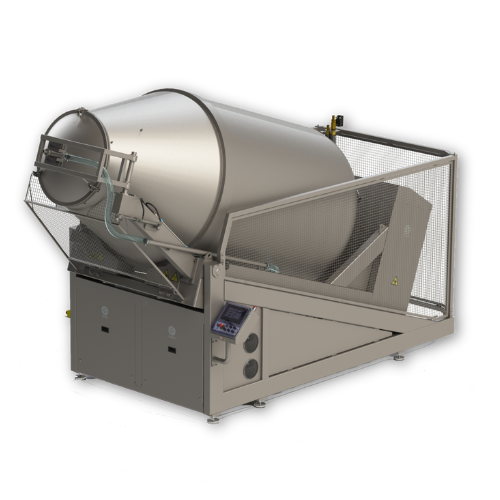

A broad range of tumblers with capacities ranging from 1600 to 10,000 liters. The tumblers are designed for massaging and marinating of a wide range of meats, they are perfectly suited to meet the demands of pork, beef, poultry, and seafood products.

The crucial and completely deciding factor in achieving the desired result when tumbling is that the products get kinetic energy / mechanical working. The binding capacity achieved is in direct relation to the movement patterns of the products inside the drum. The more the movement is in as many directions as possible per revolution, the better the effect. But the movement must be combined with a gentleness to keep the structure of the muscles intact. Cooling of the drum is also greatly significant to the end result since it counteracts the heat generated by the kinetic energy supplied and preserves the achieved binding capacity further along in the process.

The Garos MDF Tumbler is available in six different standard models with drum volumes of 1600, 2600, 3900, 5600, 7500 and 10,000 litres as well as a load capacity of up to 65% of the volume, depending on product. All sizes have the cooling jacket as a standard feature.

ADVANTAGES

Multi displacement flights (MDF) – produce unsurpassed effectiveness.

Optional scale (load cells) – advanced product weighing system

High level of hygiene – thanks to a simple cleaning and the absence of inaccessible areas

Tilted drum – hydraulic drum. Lifting and lowering system allowing for quick and easy discharge

Process automation – advanced control system and full controls of all the massaging parameters

Vacuum pumps – advanced multistage filtration system

Optional Co2/N2 – possibility of cooling the products

Optional ingredients dosing of dry and wet ingredients both manual or automatic mode

MULTI DISPLACEMENT FLIGHTS

The GAROS tumbler best answers efficiency requirements. The specially designed flights create a completely unique 4-way movement.

With the incremental positioning and the symmetrical design of the baffles, there is significantly more product movements per revolution, which is more effective without affecting the gentleness.

ADDITIONALS

Addition of wet and or dry ingredients:

Automatic dosing system for a variety of dry and wet ingredients allowing for fine tuning of production processes.

Optional weighing system combined with hoppers for dry or wet ingredients, allows many different possibilities and solutions such as connecting the system directly to brine mixers, storage tanks, and other production lines.

Advanced control of the dosing process or continuous dosing, brings many benefits to the massaging process as it contributes to increased productivity and improved product quality.

By saving recipes the system is able to automatically dose specific amounts of additives measured in kilos/percentages relative to the total amount of product in the tumbler.

Defrosting:

It is possible to add a defrosting feature to a standard Garos MDF tumbler. This option makes it possible to reduce processing time considerably when utilising frozen product.

Processors are often faced sudden production requirements faced with having to utilise products which are frozen, necessitating thawing the product as quickly and efficiently as possible. With the GAROS MDF tumbler you can circulate a heating medium through the jacket around the drum, giving excellent surface contact, (in comparison to other systems where only the baffles are heated), whilst gently tumbling the frozen products, providing a quick and controlled thawing process.

GAROS defrosting offers a speedy and cost-efficient alternative to the traditional ways of defrosting but can be used in conjunction with tempering rooms or radio frequency and microwave systems. Finishing product with GAROS vacuum defrosting delivers consistent results without incomplete defrosting or hot spots.