GBT 300 when utilising 200 litre trolleys is the complete answer to tumbling, mixing, coating, and marinating needs for whole meat products such as poultry, silversides, pork loins, minced meats, fsh, vegetables, salads etc. Minimal product damage due to gentle mixing without driven paddles or mixing arms.

Possibilities to reach a vacuum level up to 50 percent. For higher levels of vacuum, reinforced trolleys can be used. Note that the hood above the trolley has a large volume of approximately 170 liters allowing a superior mixing transfer with each revolution coupled with the 200-litre trolley containing product. This ensures a thorough tumbling/mixing/marinating of the content and also means that the trolley can be loaded to its maximum, 200 liters per work cycle.

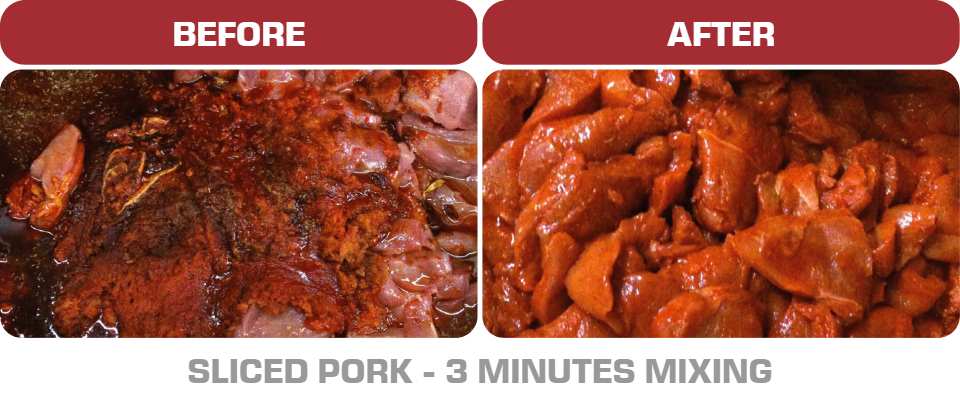

BEFORE AND AFTER LIBRARY

ADVANTAGES

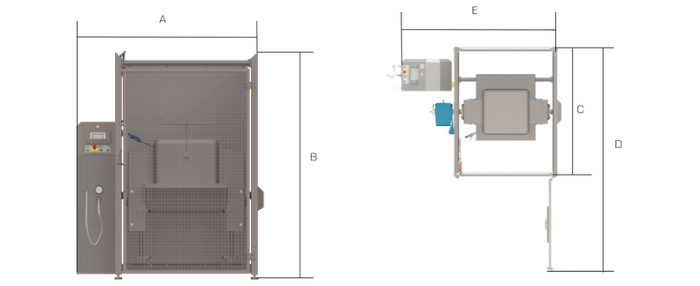

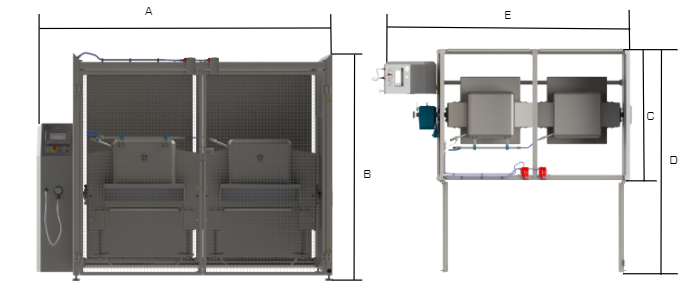

Trolley Tumbler 300/600 – Single or double machine

The range and versatility is nearly unlimited or all food products, mixing, tumbling, coating marinating

Cycle times less than 3 min for 95% of most of the products

Possibility of creating and saving 20 programs/recipes.

Works with standard 200 liter trolleys Compliant with DIN 9797 – Manages up to 200 liters of product each work cycle.

High flexibility – fast loading and unloading

Tumbling and mixing is gentle yet highly efficient at the same time.

Easy and quick cleaning with no hard to reach areas.

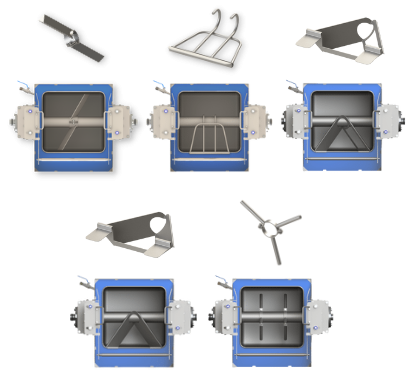

ADDITIONALS – MIXING FORKS

These are optional for the Trolley Tumbler that will make it even more functional and versatile used in conjunction with heavy or difficult product. Mixing products that previously required a long machine cycle, will no longer be a problem. In addition, their assembly / disassembly is fast and easy.

These are optional for the Trolley Tumbler that will make it even more functional and versatile used in conjunction with heavy or difficult product. Mixing products that previously required a long machine cycle, will no longer be a problem. In addition, their assembly/disassembly is fast and easy.

PRODUCTION FLOW

Batch ingredients in the trolley

Trolley pushed into the machine

Run the programmed cycle

Trolley with the finished batch discharged for further processing

TECHNICAL DETAILS